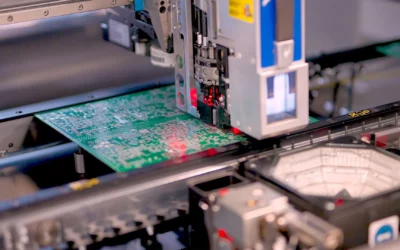

Bare Printed Circuit Boards (PCBs) and PCB Assemblies (PCBA) undergo various tests before leaving the manufacturing area. One of the most popular test methods is the Flying Probe test.

What is a Flying Probe Test?

A simple way of explaining, the Flying Probe Test (FPT) is an automated system with a small number of probes that “flies” around the top and bottom of a PCB simultaneously to make contact with the test points.

In accordance to program set up for the specific board being tested, a flying test probe is moved from one test point to another.

FPT machines have high precision needles that perform electrical tests to determine if a PCB (component) is in good condition. These tests, by not having the need to use custom tools, are a cost-effective instrument in the early stage of development and low-medium volume production.

Advantages of flying probe tests

The advantages of performing these tests are:

- Detect electrical and circuit problems, such as apertures, short circuits, capacitance and resistance ( polarity, absences, faulty soldering, wrong or defective components, tolerances…).

- Guarantee the reliability and performance of the final products.

- Minimize waste, reduce product recall and optimize safety.

Without a proper testing strategy, a business could face reduced profit margins, dissatisfied customers, and even defective product liability claims.

How does a flying probe test work?

Flying probe testing is generally preferred for low-volume and for prototype circuit boards testing as well as PCB assembly and it is also considered cost-effective and convenient for these lesser quantities.

The main advantage is, the speed of being able to have a test available in a matter of days or hours depending on the board complexity, even for higher volumes, as well as the high coverage offered by the test.

Below we discuss its operation in a few steps:

1. Create an FPT test program

- This design is intended to test the entire circuit board. This is generally done on an offline computer using an FTP test program generator application. This generally requires Gerbers, BOM and ECAD files.

- On the machine itself with a Masterboard, to define the values of the components being tested , test points, component formats, offset, debugging …. and finalize the design of the test program.

2. Upload the program to the FTP tester

The circuit board assembly requiring testing is placed on a conveyor belt inside the FTP tester and will be transported to the area where the probe is executed.

3. Application of electrical and power test signals

These tests are performed on the probe points and then the measurements are read. This processing will determine if a specific part of the PCB meets the expected results (component). Any failure or deviation from the established programs and expectations will indicate a defect in the unit, which will mean a failed test.

Why is this type of test important?

The prototyping phase is essential to evaluate and verify the design and the correct performance of a product or project. At P4Q, we offer a prototype manufacturing service oriented to the achievement of the required demanding manufacturing deadlines, reducing the Time-To-Market of our customers.

One of the complementary services to prototyping is flying probe tests, to guarantee the performance of all final products. If you require more information about our process, we invite you to contact one of our experts at P4Q.

Author: Test department P4Q