Engineering and R&D

We are Engineering Experts

Committed to your success, we work hand-in-hand with your teams to analyze your technical requirements along every stage of the project’s life-cycle from start to finish and develop a custom solution for you.

P4Q Engineering team, provides comprehensive advice and support in choosing the optimal solution to suit your individual needs and requirements. This includes, regulatory compliance, design & development, renders, prototype, testing, performance studies, and more.

R&D | Research & Development

Powered by innovation, from its origins, P4Q has shown a strong commitment for development, research and innovation applied in all the company’s business areas, production processes, Industry 4.0 and new products and services. P4Q developed the First Tracker Controller of its kind and what would become the company´s first branded product: Suntrack®.

Our highly experienced and passionate team of experts designed and created a cutting-edge technological solution for PV Solar Tracking.

P4Q continue investing in developing technologies for industries such as The Renewable and Healthcare industries.

Hardware & Software Development

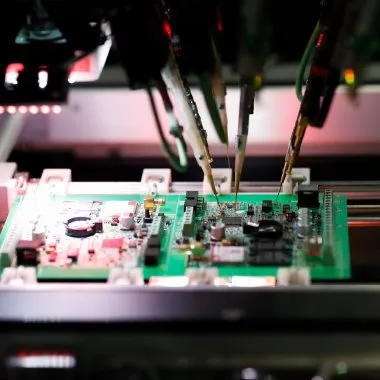

Electronics Manufacturing

We work with our customers for production-optimized PCB design and redesign, schematics and PCB Layout.

Solar Tracker Control Integration

First of its kind and born in the cloud, Suntrack® Intelligent PV Solar Tracker Control Unit (TCU) processes more than 7 Gigabytes of data daily. Our HW is complemented with powerful SW (proprietary datalogger) REST API for advanced system integration and flexibility. Our integrated system incorporates advanced monitoring technologies to further increase productivity and maximize solar energy production, and reduce costs.

The data from our sensors is collected, transferred and centralized from every site and photovoltaic plant from around the world into our cloud platform, offering industry-leading scalability, data availability, security and analysis performance.

Qassay high-precision Diagnostic Test Device

Integrated diagnostics test system including SW, HW and health information technology (health IT) tools. Incorporates technologies such as high-resolution spectrometric sensor, Cloud machine learning and analytics, it can ensure real positives, sensitivities and specificity false negatives greater than 90% through mathematical algorithms and the ability to self-learn from the diagnoses that are made.

Product Reliability Testing

Electronics Advanced Product Testing

We conduct rigorous testing and product validation. We support our customers with our own development of testing equipment, providing them direct access to the storage test results, values and traceability.

Product Quality Testing and Validation -Final Product Testing

We perform thorough testing, abiding by all the corresponding required regulatory bodies and certification protocols, assuring rigorous quality control processesing order and ensure product integrity, identify and address any product safety and performance risks as well as execute our own self-testing to ensure and validate the optimal performance of the integration of our technology into the products and solutions.