Lifecycle Management and Global Supply Chain

Global Supply Chain & Logistics

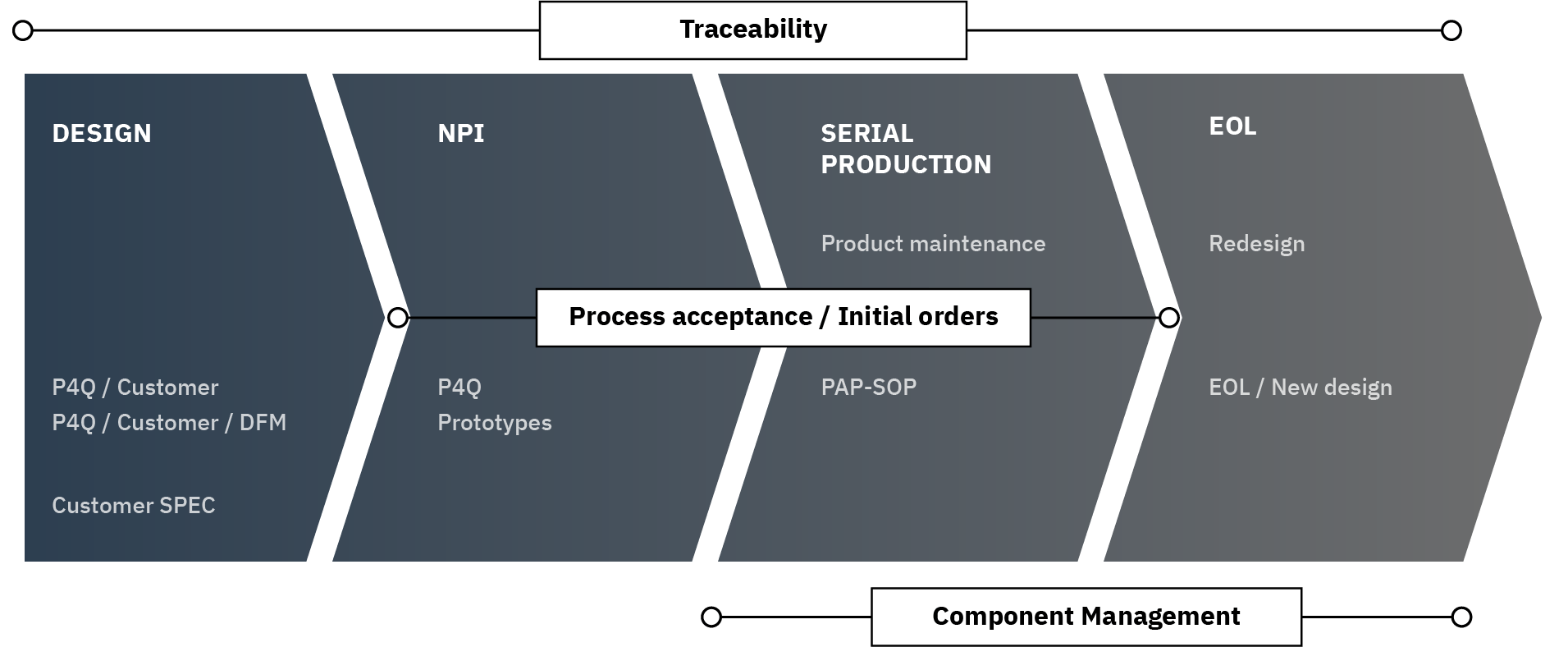

Full Traceability

Component & Obsolescence Management

Full traceability for components, tests and process

Obsolescence management process

Industrialization

Product Industrialization & NPI

Comprehensive industrialization process to ensure product reliability for serial production. Our Program Management & Engineers form a cross-functional team providing on-going support to your team and your programs.

Our dedicated engineering and supply chain teams work together from prototyping to serial production in planning for key custom material & component requirements as well as the necessary equipment, specific to your program, managing key relations with our global supply partners.

We implement sourcing strategies leveraging our global supply chain & logistics management for improved cost efficiency, meeting highest quality and faster time to market.

Design for Manufacturing (DFM)

Support for higher quality product, cost reduction and supply chain analysis right from prototyping to ramp-to-volume manufacturing.

Design for Excellence (DFX), Design for Testing (DFT)

1

Design and

data verification

2

DFM check

DFA check

3

Feasibility

& BOM Analysis

4

Components

availability

5

EMS

serial production

6

End-0f-life

management

We utilize specialized analytical tools to eliminate any errors or obstacles that may arise during production, PCB assembly, or final assembly.

This process flow can guarantee that the same products are produced consistently.

- A dedicated team

- Flexible and adaptable planning

- Avoid critical delays Time-To-Market (TTM)

- Transparency, and consistent communication on program deliverables

- Custom approach to your program needs

- Program risk mitigation plan

- Latest software technology

HQ Europe

Production Plant

Nuestra Señora de la Guía 19

48810, Alonsotegi, Vizcaya (Spain)

Phone: (+34) 94 498 2028

USA Plant

P4Q USA, INC. Production Plant

5901 Office Blvd.

Albuquerque, NM 87109

USA

Phone: + 1 50 5341 9179

China Plant

PFQ China. Production Plant

Building Q, No.88, Hongyang Road, Qiandeng Town,

Kunshan City, Jiangsu Province

Phone: 0512-36882626

© 2023 P4Q. All rights reserved.