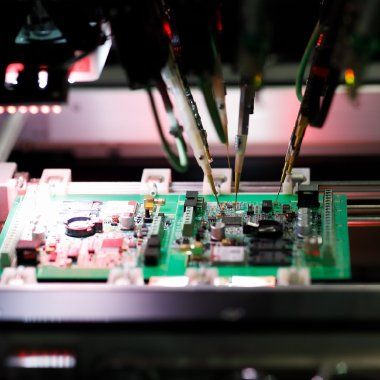

EMS (Electronic Manufacturing Services)

EMS (Electronic Manufacturing Services) & Highly Engineered Final Product

P4Q provides Full Box Build for proprietary products as well as Electronics Manufacturing & PCBA services globally for industries with the highest standards such as Automotive and the Rail industry, and have been doing so globally for over 25 years, supporting our customers projects internationally. We are ISO 9001:2008 certified consistently meeting our customers and regulatory requirements.

EMS & Box Build

We develop and manufacture electronics and electronic systems as well as Tailored-Turnkey Solutions for final products in Green Tech/Renewable Energy and Healthcare Industry (Suntrack® & Qassay), from concept, design to full production, providing high-end engineering, complete box build assembly along our printed circuit board (PCB) production, fully integrated Electro-Mechanical assembly and system integration at highest-quality, in addition to prototyping, rigorous quality assurance and more.

Technological Capabilities

- Inhouse Custom End-to-end Integrated Manufacturing

- Through hole (THT) and surface mount (SMT), Press Fit

- Automated processes

- Efficient flexible quick change-overs & line-set up

- Automatic depanelling machine (PCB separation)

- Wave Solder Machines: Ultra 2000 (Nitrogen)

- Selective Soldering

- Conformal Coating

- IPC certified in-house trainers

- Assemblies as per IPC 610 Class III standards

- Mechanical assemblies (Wire Harness, Motors, housings)

Box Build & Mechanical Assembly

- In-house PCB Assembly (PCBA)

- Product Assembly & Hardware Integration

- System Level Assembly

- Sub-assemblies & components

- Wire harness and Cable harness Assembly

- Sub-Assembly housing integration

- Motor Assembly

- LED light guide Electronics Integration

- Software & Product Configuration

- Testing & Validation

- Packaging & Labeling

- Order Fulfillment, Supply Chain & Logistics

- Full Traceability

- After Sales

Prototyping

Electronics Printed Circuit Board Assembly Prototype

We manage the full prototype process of PCBA to set your product for full-scale production with confidence. Our engineering and production teams work hand-in-hand to ensure product's DfM.

- Inhouse manufacturing

- Accelerate Time to Market (TTM)

- Product Validation

- Hardware/software testing

- Cost Control

Seamless transition from prototype production to serial manufacturing. We produce custom tooling:

- Tooling & Fixture development

- Automated Test

- Manufacturing highly complex references

(Fine pitch 0,3mm…QFN… Micro-BGAs 0201)

Product Prototype

We fully design and manufacture products (turnkey) and variation models for PV SolarTracking and Health Diagnosis Devices.

Our supply chain and engineering teams manage supply chain strategies from prototype stage to serial production.

Our team of engineers: R&D, Mechanical engineers, Process engineers, Electronics engineers…come together and work to successfully identify and tackle issues as soon as possible and reduce the risks of serial production.

We work closely with our clients for the entire project life-cycle from beginning to end, maintaining continuous communication at all stages of the project from prototypes development to finished products assuring it meets all the needed regulations and certifications, test the functionality and performance.

Production Analysis

From an early stage, we take into account multiple aspects that are crucial for Full product and PCB Assembly (PCBA). We work to achieve maximum product reliability and product quality aiming at lowest total cost.

Design to cost based on:

- Design for Manufacturing (DFM)

- Design for Testing (DFT)

- Design for Assembly (DFA)

- ESD compliant - returnable packaging design

- BOM (Open Book) Analysis

Product Realibily Testing

Electronics Printed Circuit Board Assembly Prototype

We conduct rigorous testing and product validation. We support our customers with our own development of testing equipment, providing them direct access to the storage test results, values and traceability.

- Solder Paste Inspection (SPI)

- Automated Optical Inspection (AOI)

- Flying probe test/ Electrical Performance Test

- JTAG Test Customized Product Specific Functional Tests

- Customized Test Station Electrical Safety Testing

(Dielectric Testing, Grounding) - Burn-in Testing X-ray Inspection Environmental Testing

(Climatic Chambers)

Product Quality Testing and Validation-Final Product Testing

We perform thorough testing, abiding by all the corresponding required regulatory bodies and certificationprotocols, assuring rigorousquality control processesin order and ensure product integrity, identify and address any product safety and performance risks as well as execute our own self-testing to ensure and validate the optimal performance of the integration of our technology into the products and solutions.

Facilities & Equipment

Global production, local reach for your local needs

We account for highly automated electronic manufacturing facilities in every region; North America, Europe, Asia, continuously adapting our manufacturing service to the available technologies and the market.

- Digital transformation Investment

- Customer-centric processes

- Industry 4.0 manufacturing

- Implementation of modern digital technologies

- Advanced quality control and management systems

- Lean manufacturing processes

Each of our facilities worldwide operate under strictest quality standards such as:

- ISO: 9001 standards

- AITF: 16949 for Automotive

HQ Europe

Production Plant

Nuestra Señora de la Guía 19

48810, Alonsotegi, Vizcaya (Spain)

Phone: (+34) 94 498 2028

USA Plant

P4Q USA, INC. Production Plant

5901 Office Blvd.

Albuquerque, NM 87109

USA

Phone: + 1 50 5341 9179

China Plant

PFQ China. Production Plant

Building Q, No.88, Hongyang Road, Qiandeng Town,

Kunshan City, Jiangsu Province

Phone: 0512-36882626

© 2023 P4Q. All rights reserved.